The Evolution of Metal Building Design: From Origins to Future Innovations

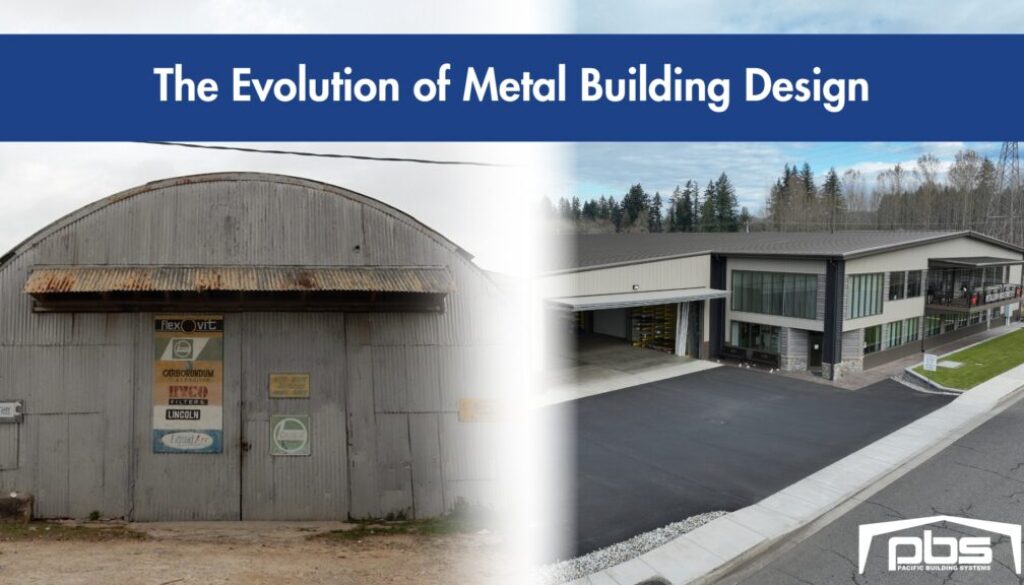

Metal building designs have come a long way since their humble origins in centuries past.

Today, nearly half of all low-rise commercial buildings in the U.S. are constructed with steel building systems, thanks to advantages like superior durability, low maintenance needs, and energy efficiency.

Pacific Building Systems (PBS) – a family-run company founded in 1962 – has been at the forefront of this evolution, delivering over 10,000 metal structures across industrial, commercial, agricultural, and government sectors in the Pacific Northwest.

In this post, we’ll explore the origins of metal buildings, what early designs looked like, how they’ve evolved, and the innovations shaping the future of steel construction. Along the way, we’ll highlight notable steel building projects that exemplify these changes, showcasing our company’s legacy of adapting to and leading modern design and engineering practices.

Origins: From Iron Mills to Quonset Huts

The story of metal buildings began over two centuries ago. The first known metal-framed structures were built in the late 1700s in England, where iron components were used for cotton mills and agricultural buildings.

These early metal designs proved more economical and far less flammable than traditional wood-and-brick construction, quickly demonstrating the safety and cost benefits of building with iron and steel. By the early 1800s, metal building techniques started appearing in the United States, though the scarcity and expense of steel limited widespread use at the time.

A major turning point came during World War II, when an urgent need for fast, portable construction led to a boom in metal building systems. The military required structures that could be prefabricated, shipped, and assembled quickly by unskilled crews – from aircraft hangars to barracks.

This demand gave rise to the iconic Quonset hut, a semicircular corrugated steel shelter that could be mass-produced and erected in a matter of hours. These WWII-era designs were intended as temporary solutions, but their performance did not go unnoticed.

Builders and architects after the war saw the benefits of metal buildings – speed of construction, strength, and portability – and began adopting them more widely for industrial and agricultural purposes once peacetime arrived.

This file is licensed under the Creative Commons Attribution-Share Alike 2.0 Generic license.

Mid-Century Evolution: The Rise of Pre-Engineered Steel Buildings

By the 1960s, pre-engineered metal buildings (PEMBs) had moved from niche use to mainstream consideration. Steel structures were increasingly recognized by architects, engineers, and owners for their exceptional durability and rapid assembly times, making them popular choices for warehouses, factories, and storage facilities.

However, early mid-century steel buildings often had a fairly basic, boxy appearance and limited design flexibility. Buyers tended to accept a trade-off: they got a building up quickly, but aesthetic options and custom features were minimal in those days.

It was in this climate that Pacific Building Systems was born. In 1962, after a devastating Columbus Day Storm hit the Pacific Northwest, four entrepreneurs founded PBS (originally Truss-T Structures, Inc.) in Woodburn, Oregon, to help rebuild local communities.

Early on, PBS handled all aspects of construction – from design to installation – focusing on delivering sturdy, quickly erected structures to replace those lost in the storm. Many of these early projects were straightforward industrial warehouses and farm buildings, reflecting the practical, no-frills style of the time.

The late 1960s and 1970s ushered in changes that would address the design limitations of early metal buildings. The advent of computer-aided design (CAD) technology in the mid-1970s was a game-changer for the industry.

Suddenly, manufacturers like PBS could do more than churn out generic shells – they could custom-engineer buildings to exact specifications, introducing greater variety in size, shape, and features. PBS was among the pioneers in embracing these tools, enabling clients to go beyond the standard rectangular box.

Want an unusual building footprint, an asymmetrical roof, or specific bays to accommodate unique equipment? By the late 1970s, PBS and other innovators were able to accommodate such requests by leveraging new design software and engineering techniques.

This era saw the emergence of the true “pre-engineered” metal building kit – a tailored solution where every beam and connection is designed for the customer’s needs but with the efficiency of prefabrication.

Modern Designs: Flexibility, Functionality, and Style

Fast forward to today, and metal building design is more advanced and versatile than ever. Pre-engineered steel buildings are now one of the most common solutions for low-rise construction, used for everything from retail centers and offices to schools and churches.

Modern steel structures are typically custom-designed and manufactured by companies like PBS to meet each customer’s requirements exactly. Nearly every aspect of the building can be optimized: engineers can choose straight or tapered columns, single-slope or gabled roofs, clear-span or multi-span frames, variable bay sizes – you name it.

The ability to integrate other components is another huge leap from the old days; today’s steel frames play nicely with materials like concrete, glass, brick, or wood accents, allowing metal buildings to achieve almost any architectural look or purpose.

In addition to structural customization, aesthetic options have greatly expanded. Whereas early metal buildings were often barebones in appearance, today’s designs can include facades with attractive color schemes, stylish entryways, and even facsimile finishes that disguise the metal panels.

The result is that a modern steel building can be indistinguishable from a traditional building in looks, yet still provide all the cost and time benefits of prefab steel. This evolution in capability has allowed PBS to expand into diverse project types and deliver buildings that are not only functional, but also visually appealing and community-friendly.

PBS Projects Showcase the Evolution

Pacific Building Systems’ portfolio over the decades reflects these advancements in metal building design. Below are a few notable PBS projects across different sectors, each exemplifying the modern capabilities of steel construction and how PBS has adapted to new design demands:

- Industrial: I&E Construction Operations Building in Woodburn, OR

PBS provided a custom-engineered steel building that merges industrial and commercial functions under one roof, demonstrating the flexibility of modern PEMBs to serve dual purposes. The structure includes features like internal crane supports and a mezzanine, tailored to the client’s operational needs. - Commercial/Recreational: Bend Rock Gym in Bend, OR

PBS’s clear-span steel design created the huge 20,000 sq. ft. open interior needed for 150+ climbing routes, bouldering areas, fitness studios, and more. This project shows how today’s steel buildings can provide expansive, column-free spaces ideal for sports and recreation facilities. - Agricultural: Scenic Valley Farms in Gervais, OR

PBS delivered a custom steel agricultural building for this third-generation family farm, supporting their seed processing, storage, and estate winery production needs. The building’s design is optimized for large farm equipment and crop storage, illustrating how modern ag structures are engineered for efficiency and longevity on the farm. - Institutional/Government: Oregon State Police Forensics Lab in Pendleton, OR

PBS manufactured the steel building system for this critical public safety institution, working to meet strict specifications for security, ventilation, and reliability. The finished lab provides the high-performance environment that forensic scientists require, showcasing the level of custom engineering possible with steel construction for specialized uses.

Each of these projects highlights PBS’s ability to leverage evolving design practices – from wide-open clear spans to integrated office space and specialized facilities – to meet the unique demands of different sectors.

PBS’s nearly six decades of experience have proven that metal buildings can be adapted to virtually any purpose without compromising on quality or aesthetics.

Looking Ahead: Innovations Shaping the Future of Steel Construction

As we look to the future, several key innovations and trends are poised to transform the steel building industry even further. Engineering advancements continue to improve the strength and resilience of steel structures, which is increasingly important as we face more extreme weather events in a changing climate.

Another major trend is sustainability and green construction. Steel is inherently an eco-friendly material – it can be recycled endlessly without loss of strength. Contemporary metal buildings are capitalizing on this by incorporating recycled materials and energy-efficient designs.

The way metal buildings are designed and engineered is also evolving rapidly. Digital tools such as Building Information Modeling (BIM) are becoming standard in the design process, allowing precise 3D modeling of structures and components.

Advanced fabrication technologies are on the horizon as well – while fully 3D-printed steel buildings are not here yet, automation in manufacturing is increasing. CNC machining and robotic welding are speeding up production and improving quality control.

These innovations mean that steel building kits of the future will be even faster to produce and easier to assemble, saving time and labor costs for customers.

PBS – Honoring a Legacy, Building the Future

From the first iron-framed mills to the sophisticated steel structures of today, the evolution of metal building design showcases a relentless pursuit of improvement – a journey that Pacific Building Systems has proudly been part of.

Over the decades, PBS has engineered and delivered thousands of buildings, each time applying the latest innovations in design and engineering to ensure our clients get the very best solution. Yet, throughout this evolution, we’ve held onto the core values that sparked our founding: customer-focused service, quality craftsmanship, and a dedication to community.

If you’re considering a modern steel building for your next project, from an agricultural barn to an advanced commercial facility, PBS is ready to partner with you and turn generations of expertise into a cutting-edge building that will stand the test of time.

Ready to start planning the future? Contact Pacific Building Systems to explore how a custom pre-engineered steel building can meet your needs today and for decades to come. With our history, our passion, and our innovative spirit, we’ll make sure your project is a shining example of the evolving legacy of metal building design.